- Flanges Types

- Blind Flanges

- Lap Joint Flanges

- Slip On Flanges

- Weld Neck Flanges

- Reducing Threaded Flanges

- Socketweld Flanges

- Flange Gaskets

- Orifice Flange

- Ring Flange

- Threaded Flanges

- Spectacle Blind Flanges

- Flanges Bolts

- High Hub Blinds Flanges

- Pressure Seal Valve

- Ball Valve

- Manifold Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Globe Valve

- Gate Valve

qatar@flanges.co

oman@flanges.co

uae@flanges.co

malaysia@flanges.co

sinagapore@flanges.co

indonesia@flanges.co

saudi@flanges.co

sudan@flanges.co

israel@flanges.co

south africa@flanges.co

kenya@flanges.co

nigeria@flanges.co

kuwait@flanges.co

Online Inquiry Form |

Rtj Flanges

Flanges ::Flange Standard, Fitting Standard, Pipe Standard, Valve Standard | ||

| ANSI Flange | DIN Flange | EN Flange |

| ASME Flange | JIS/KS Flange | GB Flange |

| GOST Flange | BS Flange | UNI / Api Flange |

| Flanges :: | ||

| Blind Flanges | Reducing Threaded Flanges | Lap Joint Flanges |

| Flange Gaskets | Threaded Flanges | Socketweld Flanges |

| Flanges Bolts | Ring Flange | Spectacle Blind Flanges |

| Weld Neck Flanges | Orifice Flange | Slip-On-Flanges |

| High Hub Blinds Flanges | ||

Metal Industries is one of the oldest manufacturers, dealer, distributor, stockist & suppliers of Blind Flanges, Reducing Threaded Flanges, Lap Joint Flanges, Flange Gaskets, Threaded Flanges, Socketweld Flanges, Flanges Bolts, Ring Flange, Spectacle Blind Flanges, Weld Neck Flanges, Orifice Flange, Slip-On-Flanges, High Hub Blinds Flanges, which are manufactured using superior grade of steel like SS Flanges / Stainless Steel Flange, 310 Flanges, 321 Flanges, 202 Flanges, 347 Flanges, 304 Flange, 316 Flanges, 316L Flanges., These Flanges are most durable and manufactures to fit in different size of Pipes. Engineers & World's Best Project Consultants use these Flanges in Machined Components, Metal Industries manufacturing Flanges & supplying to Government sector companies since 2 decades, we are approved vendor of Flanges in top notch government sector companies like ONGC, Indian Oil, NTPC, BHEL, ONGC, HPCL BPCL etc.we are also Saudi Aramco approved supplier of Flanges, we have supplied Flanges to companies involved in Equipment Manufacturing, Mining, Oil Refineries, Chemical manufacturing, Steel and Aluminum Manufacturing, Utilities and Transportation, and Industrial Construction We Also Supply & Maintain huge stock of Other Grades of Flanges like Alloy Steel Flange, A182 F1 / F5 / F9 / F11 / F22 / F91 FLANGES, Nickel Alloy 200 Flanges, Nickel Alloy 201 Flanges, S32750 Duplex Steel UNS S31803 Flanges, Flanges, Duplex Steel UNS S32205 Flanges, Carbon Steel Flanges, Copper Nickel Flange, Inconel 600, Incolloy 800 Flanges, Hastelloy, Monel 400 Flanges, ALLOY 20 FLANGES.

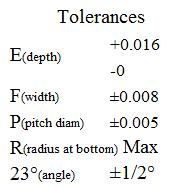

Dimensions of Ring-Joint Facings

RTJ Face Dimensions and Flange Tolerances

| Nominal Pipe Size | Groove Dimensions | Diameter of Raised Portion K | |||||||||||||||

| 150 PSI | 300 PSI | 400 PSI | 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Groove # | Pitch Dia | Depth | Width | Radius at Bottom | 150 PSI | 300 400 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Depth |

| P | E | F | R | E | |||||||||||||

| …….. | 1/2 | …….. | 1/2 | …….. | …….. | …….. | R11 | 1-11/32 | 7/32 | 9/32 | 1/32 | …….. | 2 | …….. | …….. | …….. | 7/32 |

| …….. | …….. | …….. | …….. | …….. | 1/2 | …….. | 12 | 1-9/16 | 1/4 | 11/32 | 1/32 | …….. | …….. | 2-3/8 | 2-3/8 | …….. | 1/4 |

| …….. | 3/4 | …….. | 3/4 | …….. | …….. | 1/2 | 13 | 1-11/16 | 1/4 | 11/32 | 1/32 | …….. | 2-1/2 | …….. | …….. | 2-9/16 | 1/4 |

| …….. | …….. | …….. | …….. | …….. | 3/4 | …….. | 14 | 1-3/4 | 1/4 | 11/32 | 1/32 | …….. | …….. | 2-5/8 | 2-5/8 | …….. | 1/4 |

| 1 | …….. | …….. | …….. | …….. | …….. | …….. | 15 | 1-7/8 | 1/4 | 11/32 | 1/32 | 2-1/2 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 1 | …….. | 1 | …….. | 1 | 3/4 | 16 | 2 | 1/4 | 11/32 | 1/32 | …….. | 2-3/4 | 2-13/16 | 2-13/16 | 2-7/8 | 1/4 |

| 1-1/4 | …….. | …….. | …….. | …….. | …….. | …….. | 17 | 2-1/4 | 1/4 | 11/32 | 1/32 | 2-7/8 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 1-1/4 | …….. | 1-1/4 | …….. | 1-1/4 | 1 | 18 | 2-3/8 | 1/4 | 11/32 | 1/32 | …….. | 3-1/8 | 3-3/16 | 3-3/16 | 3-1/4 | 1/4 |

| 1-1/2 | …….. | …….. | …….. | …….. | …….. | …….. | 19 | 2-9/16 | 1/4 | 11/32 | 1/32 | 3-1/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 1-1/2 | …….. | 1-1/2 | …….. | 1-1/2 | …….. | 20 | 2-11/16 | 1/4 | 11/32 | 1/32 | …….. | 3-9/16 | 3-5/8 | 3-5/8 | …….. | 1/4 |

| …….. | …….. | …….. | …….. | …….. | …….. | 1-1/4 | 21 | 2-27/32 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | …….. | 4 | 5/16 |

| 2 | …….. | …….. | …….. | …….. | …….. | …….. | 22 | 3-1/4 | 1/4 | 11/32 | 1/32 | 4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 2 | …….. | 2 | …….. | …….. | 1-1/2 | 23 | 3-1/4 | 5/16 | 15/32 | 1/32 | …….. | 4-1/4 | …….. | …….. | 4-1/2 | 5/16 |

| …….. | …….. | …….. | …….. | …….. | 2 | …….. | 24 | 3-3/4 | 5/16 | 15/32 | 1/32 | …….. | …….. | 4-7/8 | 4-7/8 | …….. | 5/16 |

| 2-1/2 | …….. | …….. | …….. | …….. | …….. | …….. | 25 | 4 | 1/4 | 11/32 | 1/32 | 4-3/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 2-/12 | …….. | 2-1/2 | …….. | …….. | 2 | 26 | 4 | 5/16 | 15/32 | 1/32 | …….. | 5 | …….. | …….. | 5-1/4 | 5/16 |

| …….. | …….. | …….. | …….. | …….. | 2-1/2 | …….. | 27 | 4-1/4 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | 5-3/8 | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 2-1/2 | 28 | 4-3/8 | 3/8 | 17/32 | 1/16 | …….. | …….. | …….. | …….. | 5-7/8 | 3/8 |

| 3 | …….. | …….. | …….. | …….. | …….. | …….. | 29 | 4-1/2 | 1/4 | 11/32 | 1/32 | 5-1/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | …….. | …….. | …….. | …….. | …….. | …….. | 30 | 4-5/8 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | …….. | …….. | 5/16 |

| …….. | 3 | …….. | 3 | 3 | …….. | …….. | 31 | 4-7/8 | 5/16 | 15/32 | 1/32 | …….. | 5-3/4 | 6-1/8 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 3 | 32 | 5 | 3/8 | 17/32 | 1/16 | …….. | …….. | …….. | …….. | 6-5/8 | 3/8 |

| 3-1/2 | …….. | …….. | …….. | …….. | …….. | …….. | 33 | 5-3/16 | 1/4 | 11/32 | 1/32 | 6-1/16 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 3-1/2 | …….. | 3-1/2 | …….. | …….. | …….. | 34 | 5-3/16 | 5/16 | 15/32 | 1/32 | …….. | 6-1/4 | …….. | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | 3 | …….. | 35 | 5-3/8 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | 6-5/8 | …….. | 5/16 |

| 4 | …….. | …….. | …….. | …….. | …….. | …….. | 36 | 5-7/8 | 1/4 | 11/32 | 1/32 | 6-3/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 4 | 4 | 4 | 4 | …….. | …….. | 37 | 5-7/8 | 5/16 | 15/32 | 1/32 | …….. | 6-7/8 | 7-1/8 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 4 | 38 | 6-3/16 | 7/16 | 21/32 | 1/16 | …….. | …….. | …….. | …….. | 8 | 7/16 |

| …….. | …….. | …….. | …….. | …….. | 4 | …….. | 39 | 6-3/8 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | 7-5/8 | …….. | 5/16 |

| 5 | …….. | …….. | …….. | …….. | …….. | …….. | 40 | 6-3/4 | 1/4 | 11/32 | 1/32 | 7-5/8 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 5 | 5 | 5 | 5 | …….. | …….. | 41 | 7-1/8 | 5/16 | 15/32 | 1/32 | …….. | 8-1/4 | 8-1/2 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 5 | 42 | 7-1/2 | 1/2 | 25/32 | 1/16 | …….. | …….. | …….. | 9-1/2 | 1/2 | |

| 6 | …….. | …….. | …….. | …….. | …….. | …….. | 43 | 7-5/8 | 1/4 | 11/32 | 1/32 | 8-5/8 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | …….. | …….. | …….. | …….. | 5 | …….. | 44 | 7-5/8 | 5/16 | 15/32 | 1/32 | …….. | …….. | …….. | 9 | …….. | 5/16 |

| …….. | 6 | 6 | 6 | 6 | …….. | …….. | 45 | 8-5/16 | 5/16 | 15/32 | 1/32 | …….. | 9-1/2 | 9-1/2 | …….. | …….. | 5/16 |

Dimensions in inches. Raised face height matches depth of groove.

Dimensions of Ring-Joint Facings

| Nominal Pipe Size | Groove Dimensions | Diameter of Raised Portion K | |||||||||||||||

| 150 PSI | 300 PSI | 400 PSI | 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Groove # | Pitch Dia | Depth | Width | Radius at Bottom | 150 PSI | 300 400 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Depth |

| P | E | F | R | E | |||||||||||||

| …….. | …….. | …….. | …….. | …….. | 6 | …….. | R46 | 8-5/16 | 3/8 | 17/32 | 1/16 | …….. | …….. | …….. | 9-3/4 | …….. | 3/8 |

| …….. | …….. | …….. | …….. | …….. | …….. | 6 | 47 | 9 | 1/2 | 25/32 | 1/16 | …….. | …….. | …….. | …….. | 11 | 1/2 |

| 8 | …….. | …….. | …….. | …….. | …….. | …….. | 48 | 9-3/4 | 1/4 | 11/32 | 1/32 | 10-3/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 8 | 8 | 8 | 8 | …….. | …….. | 49 | 10-5/8 | 5/16 | 15/32 | 1/32 | …….. | 11-7/8 | 12-1/8 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | ……. | …….. | 8 | …….. | 50 | 10-5/8 | 7/16 | 21/32 | 1/16 | …….. | …….. | …….. | 12-1/2 | …….. | 7/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 8 | 51 | 11 | 9/16 | 29/32 | 1/16 | …….. | …….. | …….. | …….. | 13-3/8 | 9/16 |

| 10 | …….. | …….. | …….. | …….. | …….. | …….. | 52 | 12 | 1/4 | 11/32 | 1/32 | 13 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 10 | 10 | 10 | 10 | …….. | …….. | 53 | 12-3/4 | 5/16 | 15/32 | 1/32 | …….. | 14 | 14-1/4 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | 10 | …….. | 54 | 12-3/4 | 7/16 | 21/32 | 1/16 | …….. | …….. | …….. | 14-5/8 | …….. | 7/16 |

| …….. | …….. | …….. | …….. | …….. | …….. | 10 | 55 | 13-1/2 | 11/16 | 1-3/16 | 3/32 | …….. | …….. | …….. | …….. | 16-3/4 | 11/16 |

| 12 | …….. | …….. | …….. | …….. | …….. | …….. | 56 | 15 | 1/4 | 11/32 | 1/32 | 16 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 12 | 12 | 12 | 12 | …….. | …….. | 57 | 15 | 5/16 | 15/32 | 1/32 | …….. | 16-1/4 | 16-1/2 | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | …….. | 12 | …….. | 58 | 15 | 9/16 | 29/32 | 1/16 | …….. | …….. | …….. | 17-1/4 | …….. | 9/16 |

| 14 | …….. | …….. | …….. | …….. | …….. | …….. | 59 | 15-5/8 | 1/4 | 11/32 | 1/32 | 16-3/4 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | …….. | …….. | …….. | …….. | …….. | 12 | 60 | 16 | 11/16 | 1-5/16 | 3/32 | …….. | …….. | …….. | …….. | 19-1/2 | 11/16 |

| …….. | 14 | 14 | 14 | …….. | …….. | …….. | 61 | 16-1/2 | 5/16 | 15/32 | 1/32 | …….. | 18 | …….. | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | 14 | …….. | …….. | 62 | 16-1/2 | 7/16 | 21/32 | 1/16 | …….. | …….. | 18-3/8 | …….. | …….. | 7/16 |

| …….. | …….. | …….. | …….. | …….. | 14 | …….. | 63 | 16-1/2 | 5/8 | 1-1/16 | 3/32 | …….. | …….. | …….. | 19-1/4 | …….. | 5/8 |

| 16 | …….. | …….. | …….. | …….. | …….. | …….. | 64 | 17-7/8 | 1/4 | 11/32 | 1/32 | 19 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 16 | 16 | 16 | …….. | …….. | …….. | 65 | 18-1/2 | 5/16 | 15/32 | 1/32 | …….. | 20 | …….. | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | 16 | …….. | …….. | 66 | 18-1/2 | 7/16 | 21/32 | 1/16 | …….. | …….. | 20-5/8 | …….. | …….. | 7/16 |

| …….. | …….. | …….. | …….. | …….. | 16 | …….. | 67 | 18-1/2 | 11/16 | 1-3/16 | 3/32 | …….. | …….. | …….. | 21-1/2 | …….. | 11/16 |

| 18 | …….. | …….. | …….. | …….. | …….. | …….. | 68 | 20-3/8 | 1/4 | 11/32 | 1/32 | 21-1/2 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 18 | 18 | 18 | …….. | …….. | …….. | 69 | 21 | 5/16 | 15/32 | 1/32 | …….. | 22-5/8 | …….. | …….. | …….. | 5/16 |

| …….. | …….. | …….. | …….. | 18 | …….. | …….. | 70 | 21 | 1/2 | 25/32 | 1/16 | …….. | …….. | 23-3/8 | …….. | …….. | 1/2 |

| …….. | …….. | …….. | …….. | …….. | 18 | …….. | 71 | 21 | 11/16 | 1-3/16 | 3/32 | …….. | …….. | …….. | 24-1/8 | …….. | 11/16 |

| 20 | …….. | 20 | …….. | …….. | …….. | …….. | 72 | 22 | 1/4 | 11/33 | 1/32 | 23-1/2 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 20 | …….. | 20 | …….. | …….. | …….. | 73 | 23 | 3/8 | 17/32 | 1/16 | …….. | 25 | …….. | …….. | …….. | 3/8 |

| …….. | …….. | …….. | …….. | 20 | …….. | …….. | 74 | 23 | 1/2 | 25/32 | 1/16 | …….. | …….. | 25-1/2 | …….. | …….. | 1/2 |

| …….. | …….. | …….. | …….. | …….. | 20 | …….. | 75 | 23 | 11/16 | 1-5/16 | 3/32 | …….. | …….. | - | 26-1/2 | …….. | 11/16 |

| 24 | …….. | …….. | …….. | …….. | …….. | …….. | 76 | 26-1/2 | 1/4 | 11/32 | 1/32 | 28 | …….. | …….. | …….. | …….. | 1/4 |

| …….. | 24 | 24 | 24 | …….. | …….. | …….. | 77 | 27-1/4 | 7/16 | 21/32 | 1/16 | …….. | 29-1/2 | …….. | …….. | …….. | 7/16 |

| …….. | …….. | …….. | …….. | 24 | …….. | …….. | 78 | 27-1/4 | 5/8 | 1-1/16 | 3/32 | …….. | …….. | 30-3/8 | …….. | …….. | 5/8 |

| …….. | …….. | …….. | …….. | …….. | 24 | …….. | 79 | 27-1/4 | 13/16 | 17/16 | 3/32 | …….. | …….. | …….. | 31-1/4 | …….. | 13/16 |

Dimensions in inches. Raised face height matches depth of groove.

Dimensional Tolerances B16.5 - 2003

| Threaded, Socket-Welding, Slip-On, Lap Joint, and Blind | Weld Neck | |||||

| Outside Diameter (1) | when the O.D. is 24" or less | ±1/16" | Outside Diameter (1) | when the O.D. is 24" or less | ±1/16" | |

| when the O.D. is over 24" | ±1/8" | when the O.D. is over 24" | ±1/8" | |||

| Inside Diameter | Threaded | within limites on boring gauge | Inside Diameter | = 10" | ±1/32" | |

| Socket-Welding, Slip-On and Lap-Joint | = 10"+1/32", -0" =12"+1/16",-0" | 12" through 18" | ±1/16" | |||

| = 20" | +1/8", -1/16" | |||||

| Outside Diameter of Hub (1) | = 12" | +3/32", -1/16" | Diameter of Contact Face | 1/16" Raised Face | ±1/32" | |

| = 14" | ±1/8" | 1/4" Raised Face Tongue & Groove Male, Famale | ±1/64" | |||

| Diameter of Contact Face | 1/16" Raised Face | ±1/32" | Diameter of Hub at Base (1) | when Hub Base is 24" or less | +1/16" | |

| 1/4" Raised Face Tongue & Groove Male, Famale | ±1/64" | when Hub Base is over 24" | ±1/8" | |||

| Diameter of Counterbore | Same as for Inside Diameter | Diameter of Hub at Point of Welding | NPS = 5" | +3/32", -1/32" | ||

| NPS = 6" | +5/32". -1/32" | |||||

| Drilling | Bolt Circle | ±1/16" | Drilling | Bolt Circle | ±1/16" | |

| Bolt Hole Spacing | ±1/32" | Bolt Hole Spacing | ±1/32" | |||

| Concentricity of Bolt Circle with Respect to Facing | NPS = 2 1/2", 1/32" max | Concentricity of Bolt Circle with Respect to Facing | NPS = 2 1/2" 1/32" max | |||

| NPS = 3", 1/16" max | NPS = 3" 1/16" max | |||||

| Thickness | = 18" | +1/8", -0" | Thickness | = 18" | +1/8", -0" | |

| = 20" | +3/16",-0" | = 20" | +3/16",-0" | |||

| Length Through the Hub (1) | = 18" | +1/8", -1/32" | Length Through the Hub | NPS = 4" | ±1/16" | |

| 5 = NPS = 10" | +1/16", -1/8 | |||||

| = 20" | +3/16", -1/16" | = 12" | +1/8", -3/16 | |||

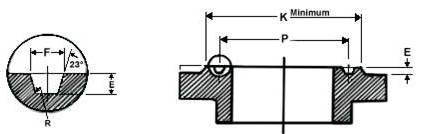

Welding Bevel Standards

for Wall Thickness "t" 3/16" to 3/4" incl. for Wall Thickness "t" greater than 3/4"

We export to: Exporter & Suppliers of Rtj Flanges in uae, saudi arabia, qatar, oman, malaysia, sinagapore, indonesia, sudan, israel, south africa, kenya etc.

Flanges Packing

Metal Industries also emphasis on the packaging . The Rtj Flanges are packed in wooden corrugated boxes foiled in bubble wraps.

|  |  |

|  |  |

|  |  |

We are exporting Rtj Flanges to more than 40 countries like UAE, EGYPT, TURKEY, uae, saudi arabia, qatar, oman, malaysia, sinagapore, indonesia, sudan, israel, south africa, kenya, Malaysia, Iran, Iraq, Saudi Arabia, Bahrain, Qatar, yemen, Kuwait, Argentina, Palestin, Algeria, Italy, Tunisia, Oman, Mauritania, USA, Bangladesh, Lebanon, Canada, Vietnam, INDIA, Sudan, Syria, Morocco, Libya, Jordon, And many more.

we also have our sales representatives to understand the requirements of our clients, we maintain ready stock of Rtj Flanges in Cities like Abu Dhabi, Riyadh, Manama, Muscat, Doha, Dubai, Damascus, Khartoum, Beirut, Jeddah, Aleppo, Alexandria, Algiers, Amman, Mosul, Cairo, Baghdad, Dammam, Casablanca, Basra, Mecca, Tripoli, Rabat, Sana'a, Arbil, Hilla, Port Said, Marrakech, Medina, Al Hudaydah, Omdurman, Damietta, Homs, Kafr Dawar, Benghazi, Fez, Bahri, Nouakchott, Sulaymaniyah, Safi, Zarqa, Oran, Kirkuk, Ismailia, Tunis, Agadir, Tangier, Sharjah, Shibin El Kom, Misratah, Matrah, Aden, Najaf, Karbala, Latakia, Sousse, Meknes, Gaza, Fallujah, Aswan, Kassala, Al-Ubayyid, Sohag, Kuala Lumpur, Penang, Kuching & many more.